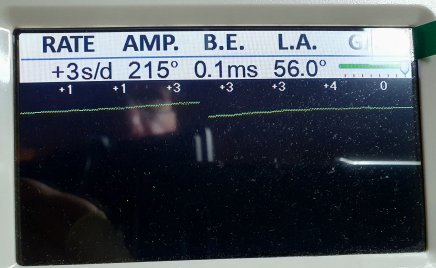

Now that the watch has been running for a couple of weeks, the amplitude has actually risen by around 20 degrees at max and settles at 235 if it winds up by wearing. The power reserve hovers around 60 hours and after 24 hours the amplitude is 210 so technically the amp it is "in spec". Manual winding still results (I suspect) in excessive slippage of the main spring. Nikz suggested to open the barrel and try doing a cleanup of it as well, so I will probably try to do that when I next open the watch.

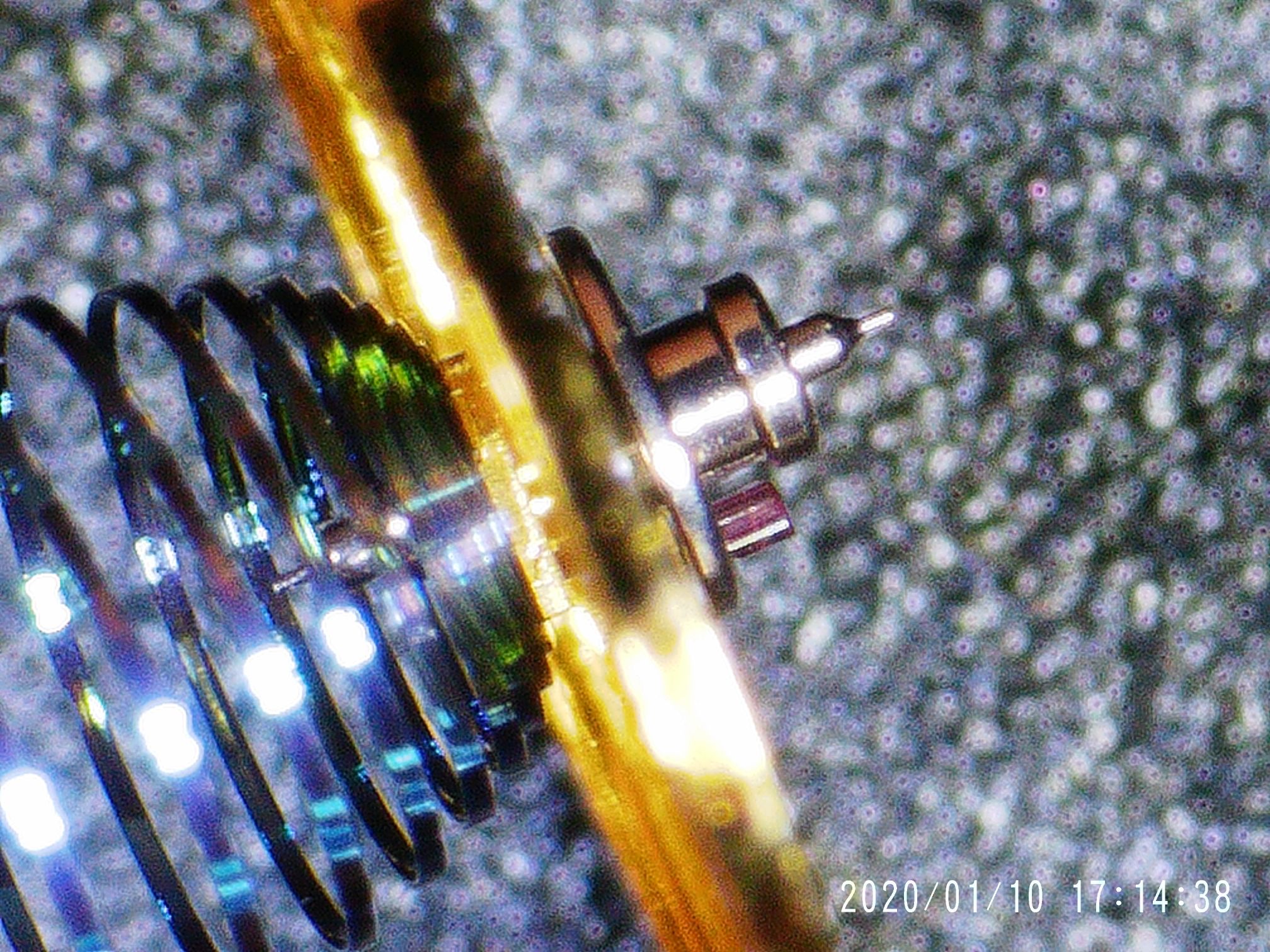

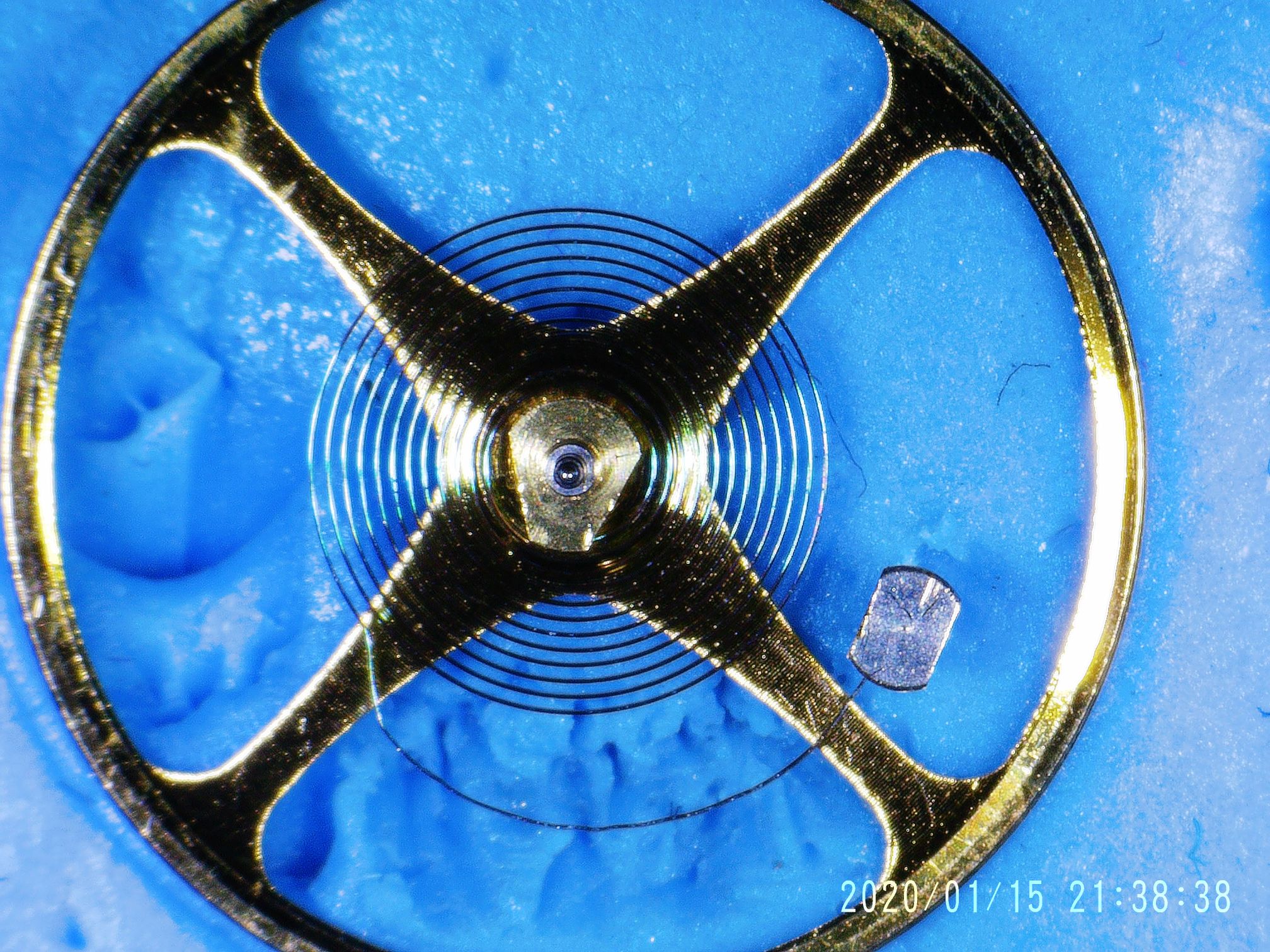

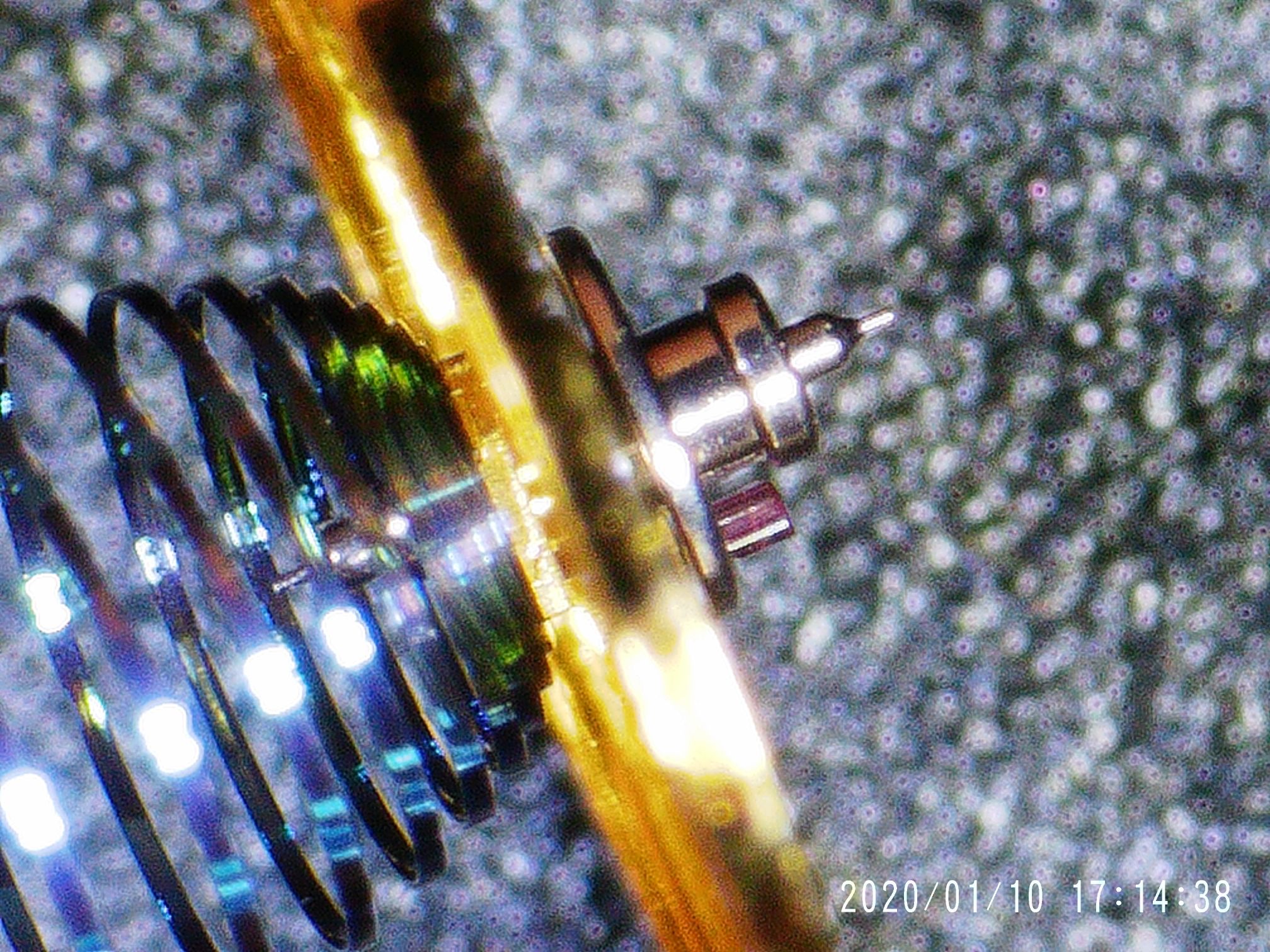

I also managed to rescue the SD card where I had the balance spring pictures (please disregard the dates, the time resets when the microscope is powered off). In the first pic the balance staff is fine:

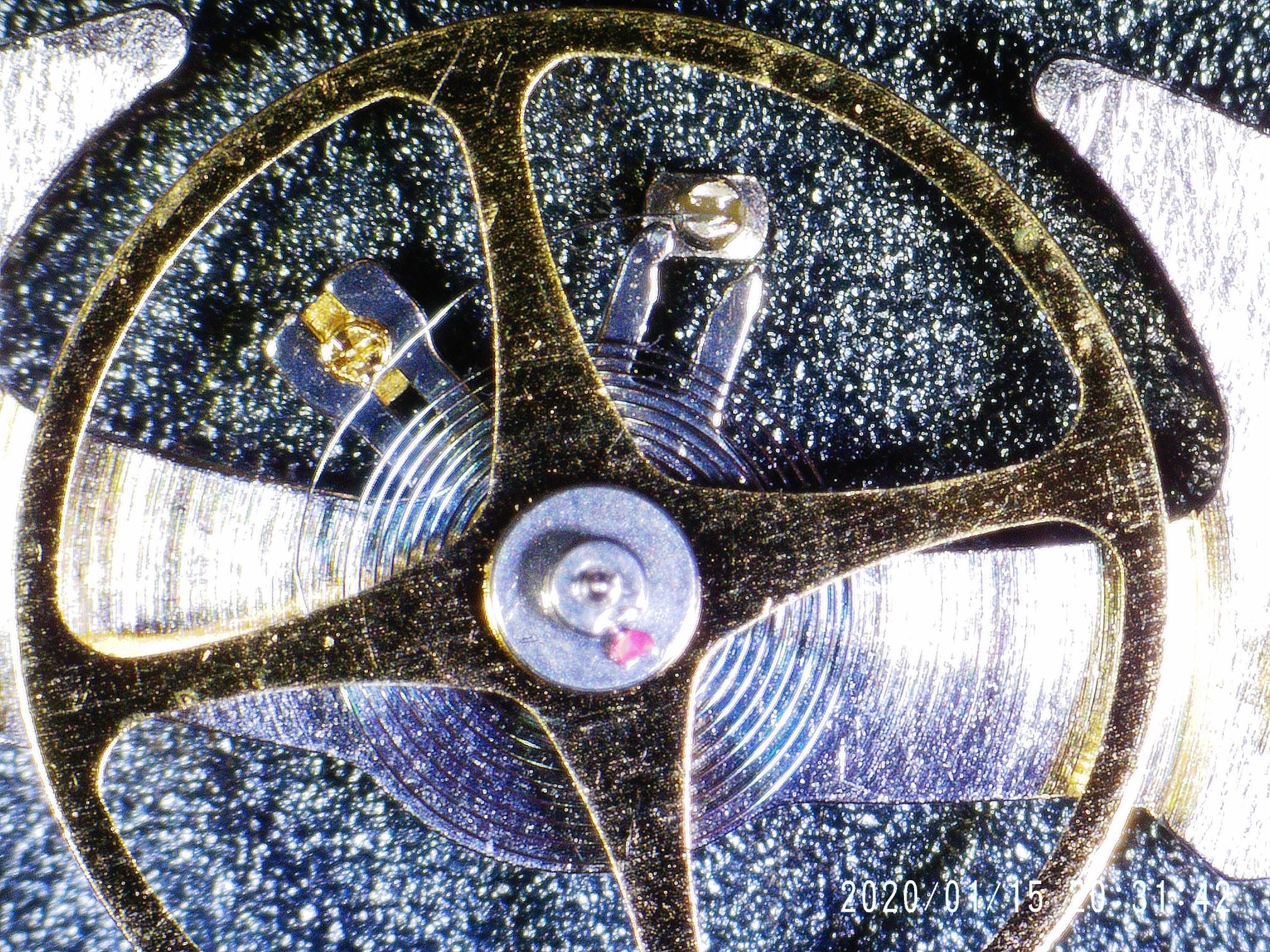

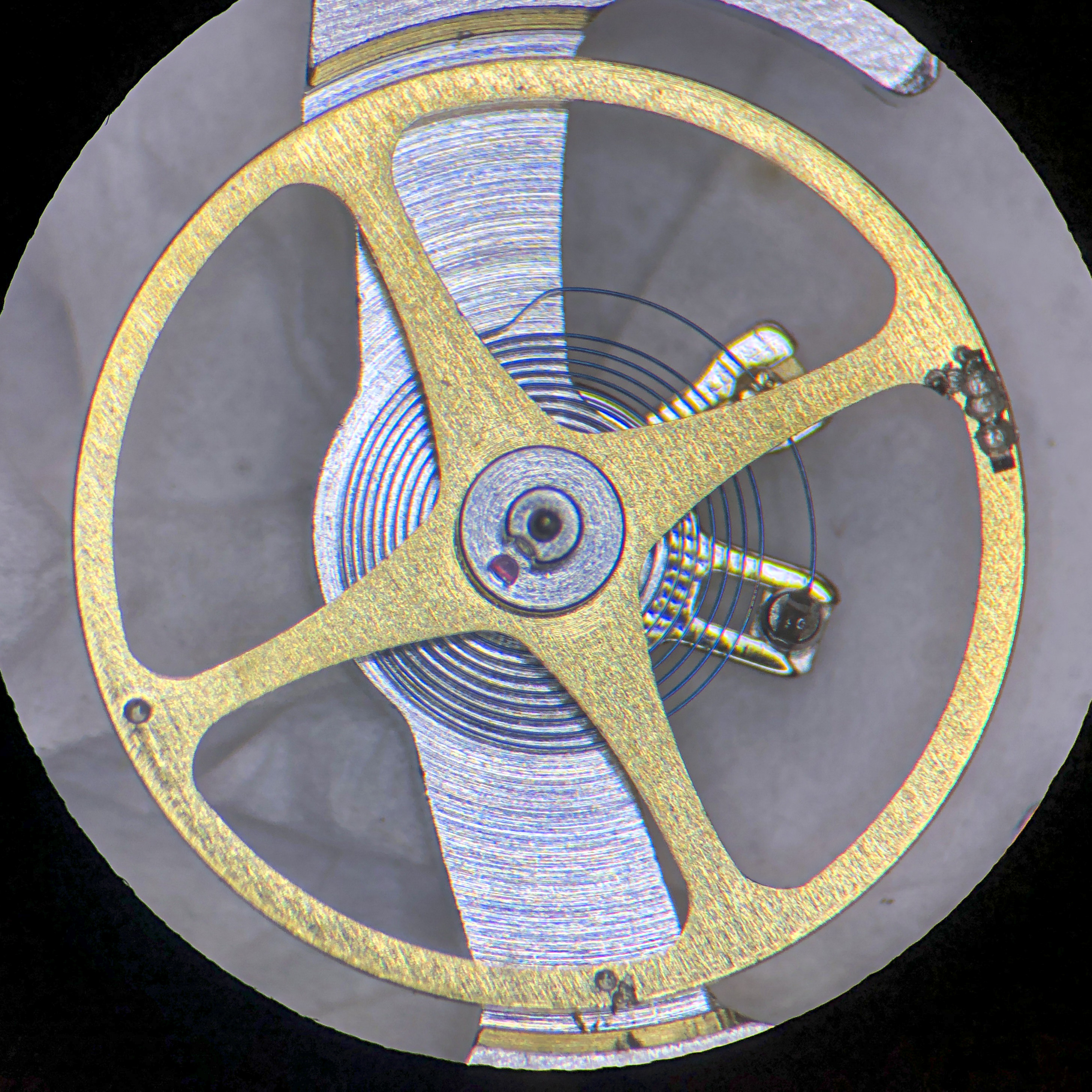

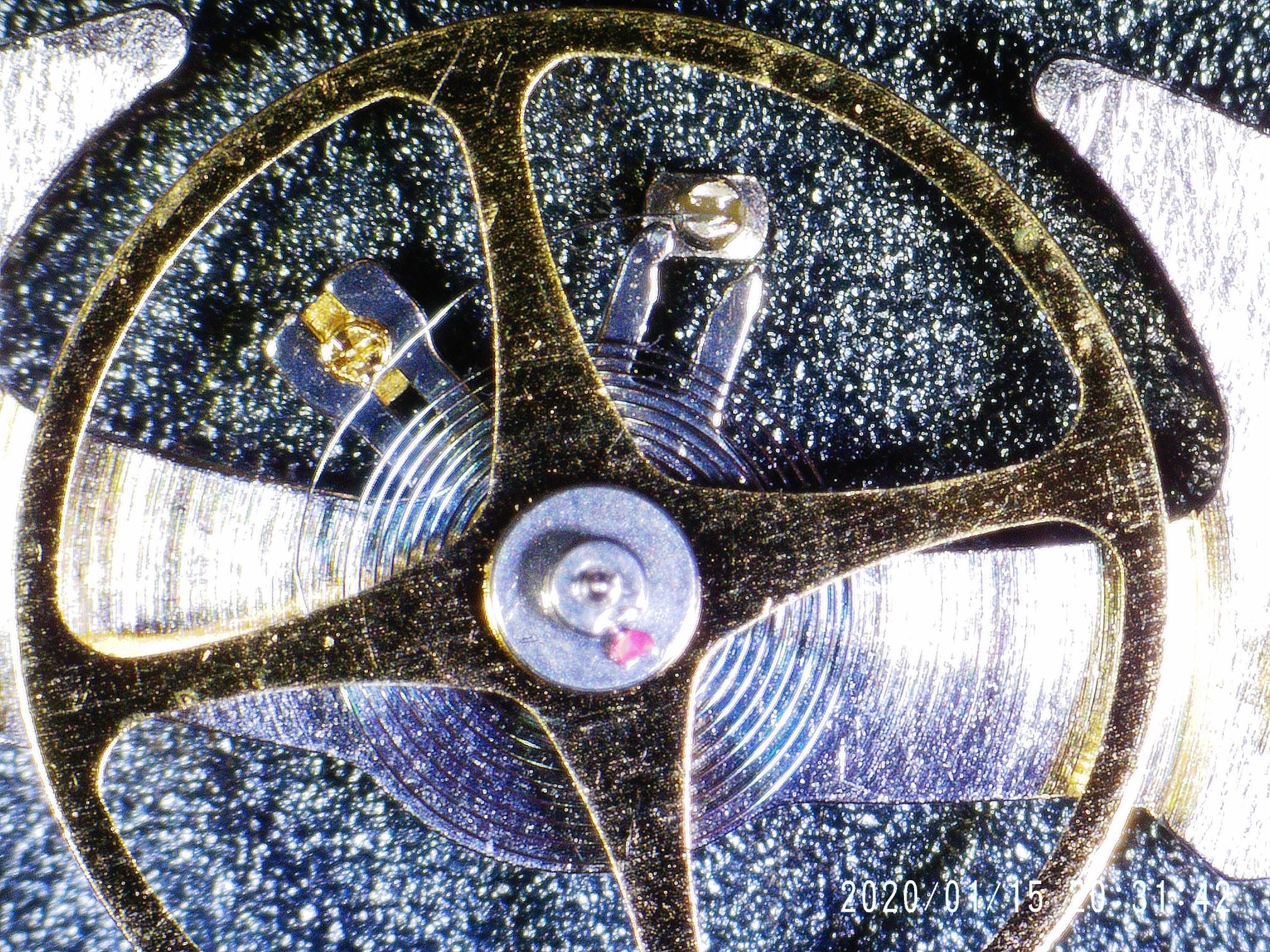

The balance spring is badly out of poise. The adjustment stud also was turned somewhat sideways which exacerbated the issues:

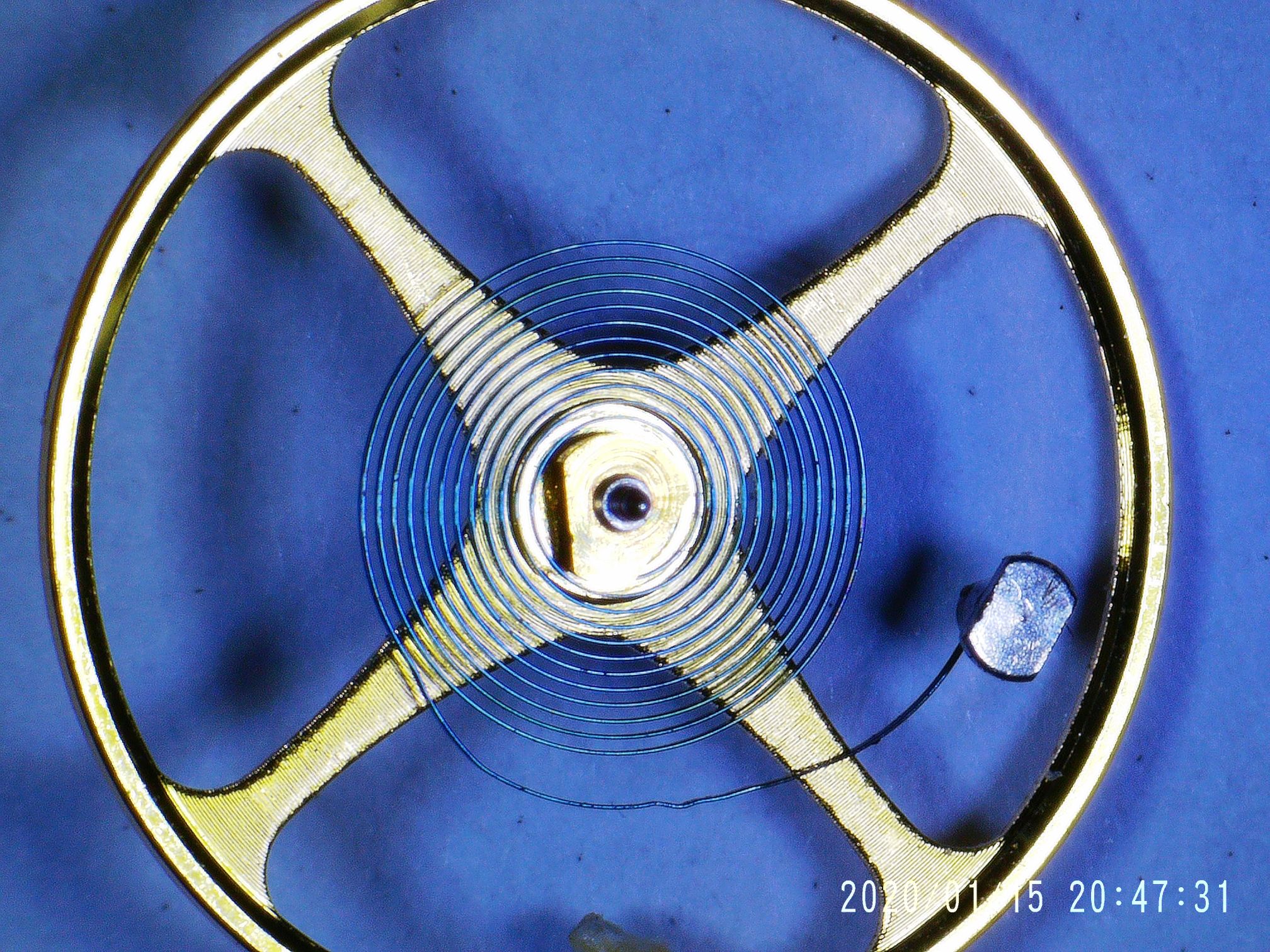

Here you can see how badly the spring is out of alignment. The person who did the "adjustment" (probably at the QC phase) seems to have botched the job entirely and also managed to kink the spring with the adjustment stud.

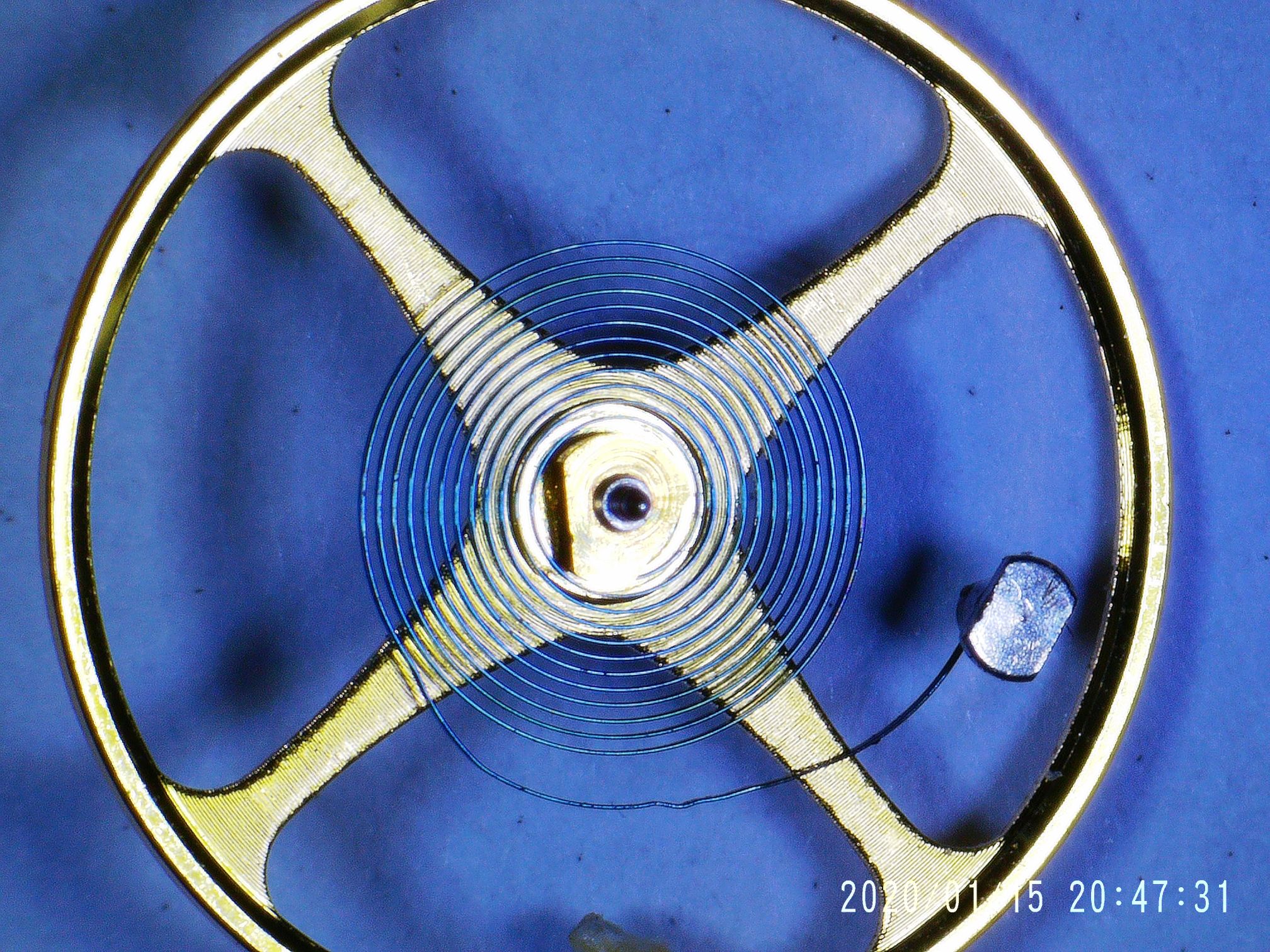

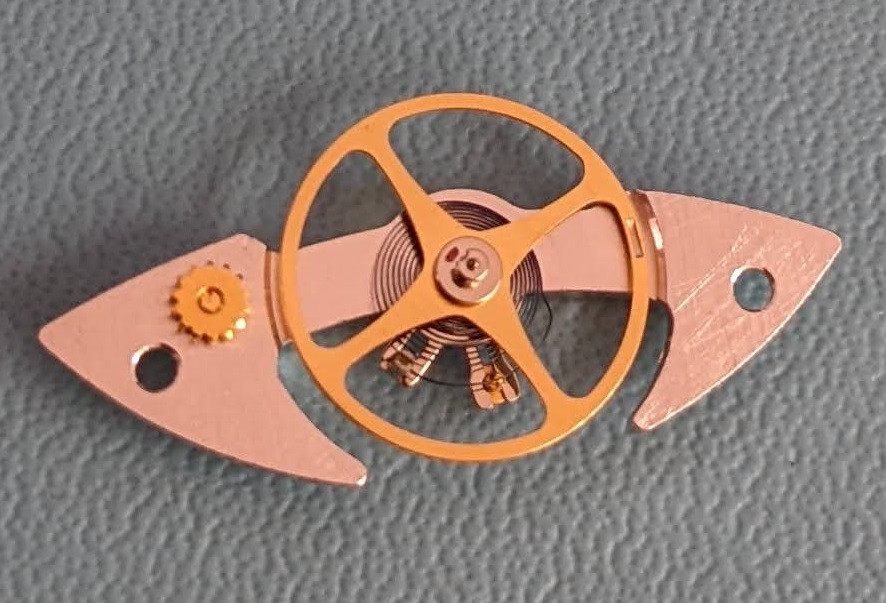

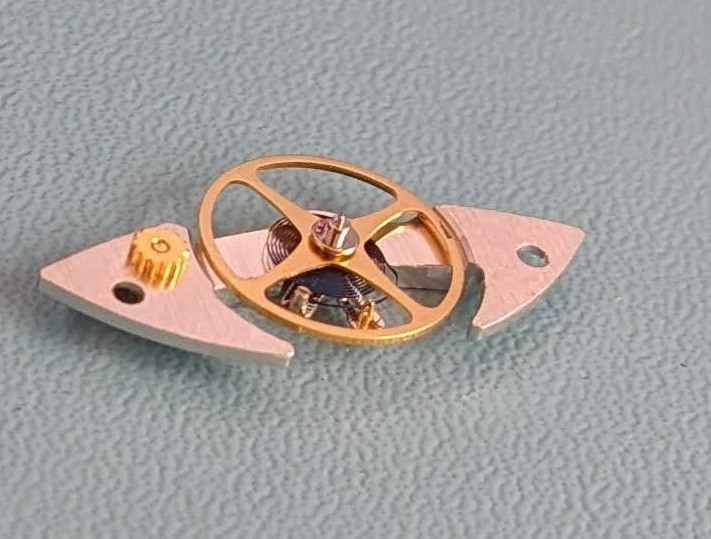

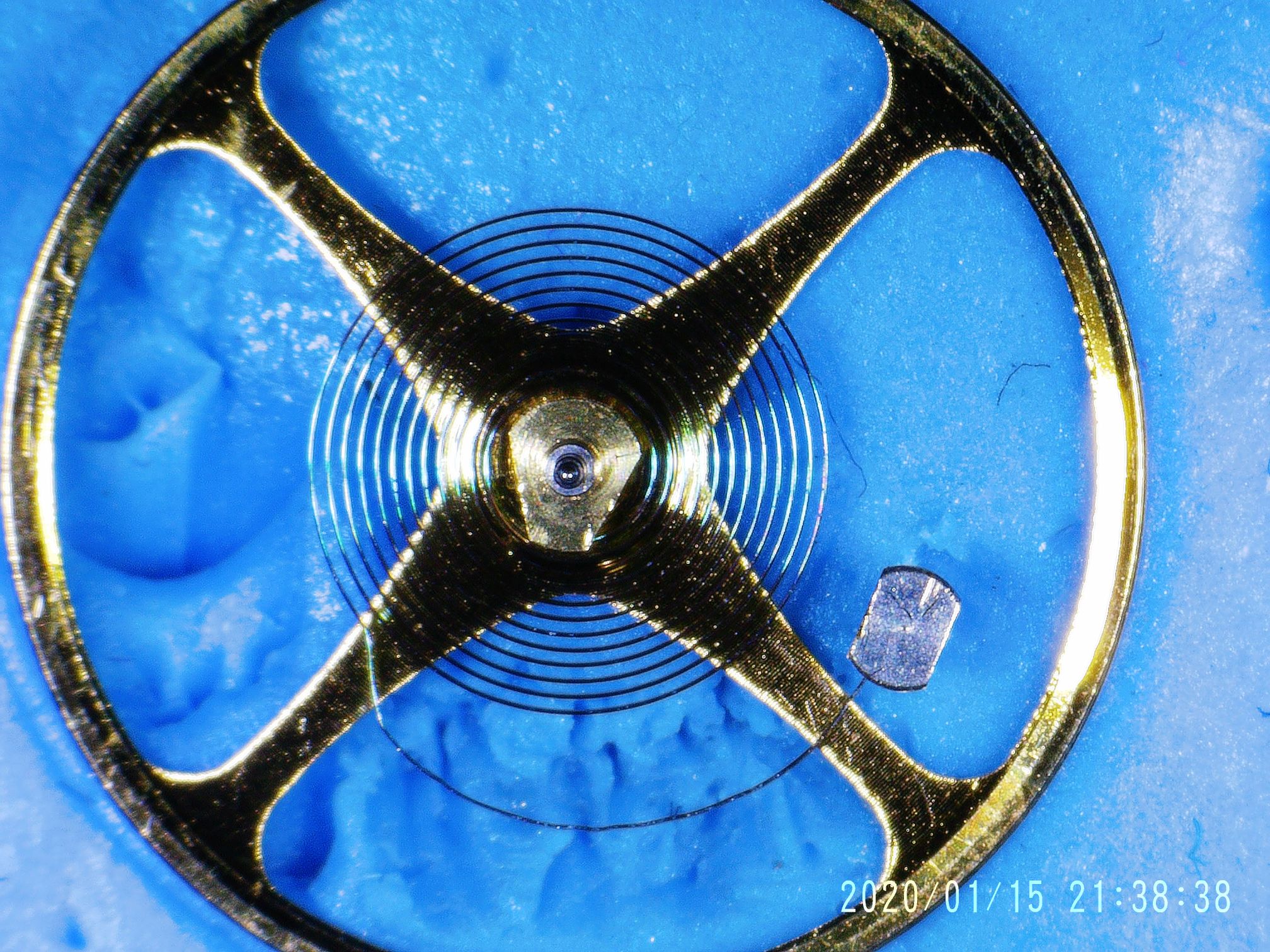

Almost there. I fixed the extension angle and adjusted the end of the spring gradually to keep the distance to the previous winding constant. Some small adjustments were still necessary after placing the balance staff in the bridge. This is still far from perfect and an actual watch smith would probably be amused, but at least it works now

Side note: I find that blu tack is very useful for this kind of precision work. It resists enough to allow me to carefully push the piece of the spring I am adjusting but gives in if I push too forcefully. Also of course it keeps the small pieces in place.